Description

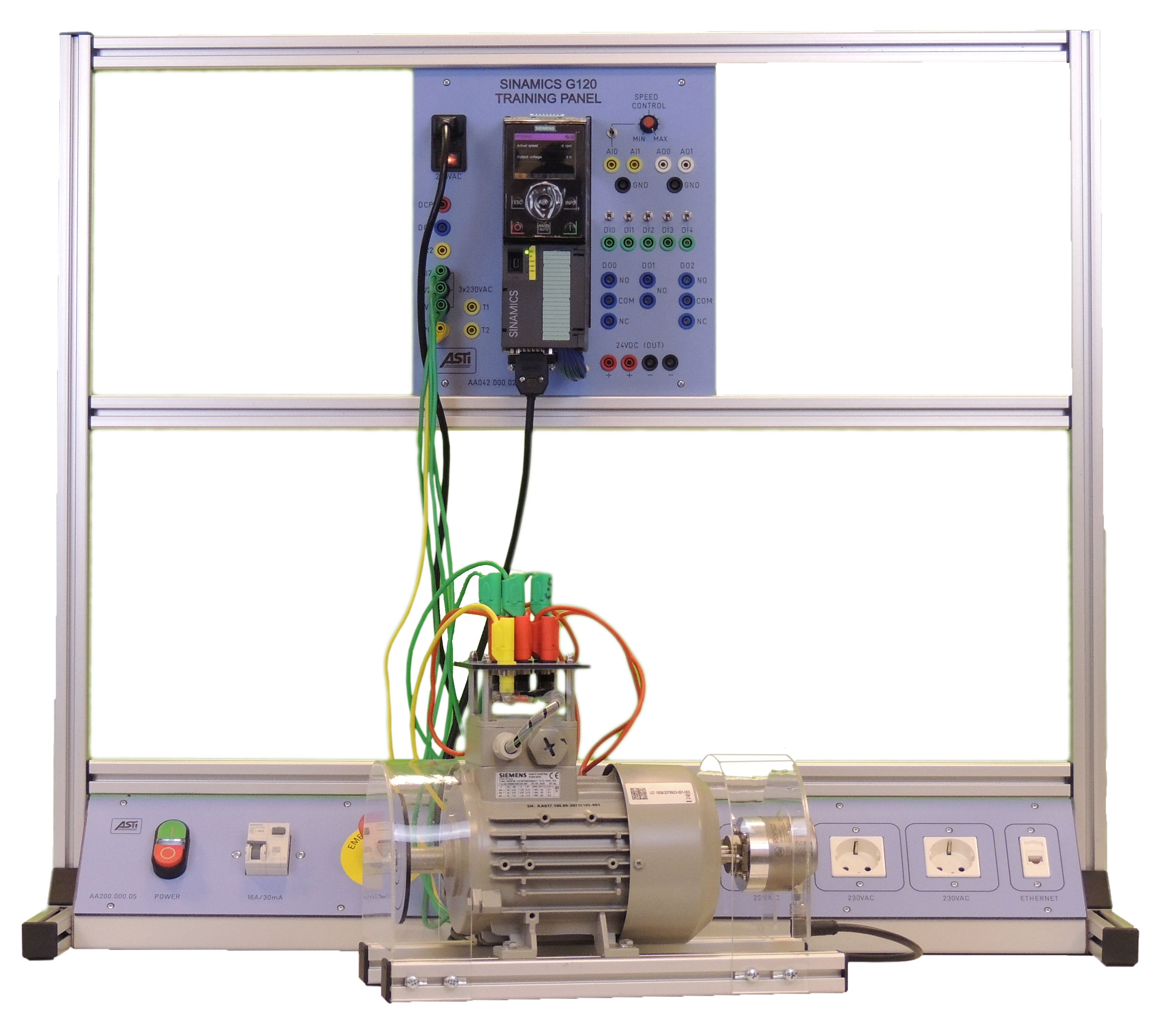

The need for speed control according to various parameters in the industrial process via frequency converters is essential in modern automation applications. This course will provide the knowledge to learn structured and efficient principles and notions about the applicability, utility, choice and configuration of frequency converters according to the technological process characteristics. Parametrization, measurement and monitoring applications will be carried out through structures involving frequency converters.

Target group: Electricians, engineers and system operators

Content:

• Symbols and electrical schemes for frequency inverter installations

• Basic structure of a frequency converter (power electronics, control electronics)

• The design, operation and installation of a frequency converter

• User interface – parametrization and configuration

• Industrial communication protocols (PROFINET)

• Techniques for optimizing industrial processes by using frequency

• Design and implementation of practical applications: motor control, starting of start-delta, acceleration and deceleration control

Objectives:

At the end of this seminar, the trainees will be able to:

• Design an electrical scheme for frequency installations

• Interpret the characteristics of a frequency converter

• Use the frequency converter interface

• Parameterize and program a frequency converter

• For an overview of the industrial processes that require the use of frequency converter

• Understand the structure, principles of operation and installation of a frequency converter

Duration: 3 days

Note: Enrollment and participation in this course requires basic knowledge in the field